There is always something new to report at Hörr.

Here you will find the latest news from our world of CNC technology – the production of stainless steel precision turned parts, as well as the operational developments making us fit for the future.

At the beginning of December, two state-of-the-art Star* CNC turning machines were delivered – a major step forward in expanding our production capabilities.

For our customers, this means increased capacity, shorter delivery times, and even greater flexibility for both small-batch and series production orders. With these additional machines, we are enhancing our processes to execute projects even more efficiently in the future.

Sixty years ago, Josef Hörr Sr. founded a small company for turned parts in Villingendorf. Today, the owner families can look back on good – sometimes eventful – times. All in all, it is a success story – one that every employee has contributed to over the past six decades. Even under the current economic conditions, there is every reason to look ahead with optimism.

Josef Hörr wants more and is breaking new ground – entering the field of metal processing.

1965 / IMPULSE

In the 1950s, Josef Hörr Sr. came to work on the Neckarburg farm. He is an exceptionally enterprising, skilled craftsman – and so the idea of manufacturing turned parts begins to take shape in his mind. Without formal training, but full of drive and a readiness to take risks, he began metalworking in the basement together with his sons Josef Jr. and Manfred.

The Hörr brothers rely heavily on standard parts in production.

1980 / EXPANSION

In 1965, the first factory building, approximately 400 square metres in size, was built for production and with offices at the current company location. Only two years later, the father died and the sons took over the management. At that time, the Hörr company was a classic family business with no employees. The company mainly manufactures standard parts and sells them to dealers. Business is going well, and consistent investments are made in new indexing machines for series production. The first external employees are also recruited. In 1982, the Hörr brothers built an urgently needed extension of around 500 square metres.

The company’s third generation brings in fresh ideas.

1990 / RELAUNCH

At the beginning of the 1990s, Josef Hörr Jr.’s two children, Andrea and Thomas joined the company. Andrea Schneider is reorganising everyday office life; the alignment of the product portfolio also requires more differentiated production planning. Another step forward: the first ERP system in administration. Thomas Hörr, machining mechanic and technician, has extensive expertise. He initiates the change from standard parts production to a focus on customer-specific drawing parts.

2000 / GROWTH

With strong solidarity and entrepreneurial courage, we succeed in overcoming the challenges of constant growth. In the mid-1990s, capacities were expanded through the construction of a 1,000 sqm production hall and the purchase of new machinery. There is 400 square metres more space for the company administration. For the first time, the company is offering training in technical and commercial areas – some of the trainees from that time are still working at Hörr today. In 1998, Andrea Schneider and Thomas Hörr officially took over management of the company.

The focus on stainless steel is a key difference maker.

2010 / RENEWAL

“How can Hörr differentiate itself from the competition?”. This is a fundamental question. The answer: through extremely sophisticated, complex, stainless steel turned parts. Thanks to its specialisation, the company soon became one of the leading providers in this field. All machinery is converted to CNC machining. The company’s latest systems stand out with maximum precision and high cost-effectiveness. Investments in the latest technologies have always been a hallmark of Hörr.

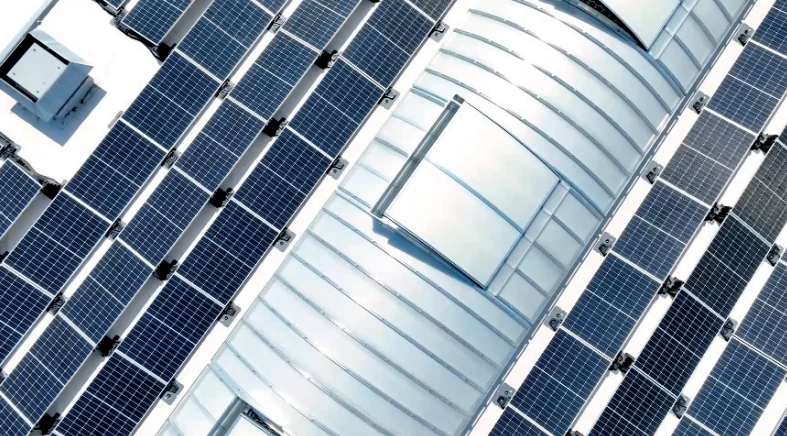

As an established company, we take responsibility for our employees, but also for future generations. That is why we attach great importance to resource protection and sustainability within our value chain. By installing a large-scale photovoltaic system on the roof of our company building in 2023, we will be able to cover part of our energy needs with ecologically generated electricity.

Transparency and openness toward our customers are at the core of the company’s philosophy. This applies in particular to our commitment to environmental and climate protection. We have demonstrated our commitment in this area through various audits and successfully obtained the corresponding certifications. We are proud of this – and constantly working to do more.

When it comes to medical technology components subject to the most stringent requirements, more and more companies are turning to Hörr Metalltechnik. We combine decades of expertise with state-of-the-art manufacturing methods to produce customised stainless steel components for medical technology, where hygiene and durability are absolutely crucial.Thanks to our sophisticated quality management system, our products reliably and consistently meet the highest standards – for your innovations in the service of health.